In the heart of modern manufacturing, CNC milling and turning processes stand as pillars of precision and efficiency. Let’s delve into the intricate world of these machining techniques and uncover the magic behind their seamless operations.

Understanding CNC Milling

CNC milling, a cornerstone of Bredo’s manufacturing arsenal, transforms raw materials into intricately crafted components with unparalleled precision. Here’s how the process unfolds – CNC Milling Source

Material Mastery

The journey begins with the selection of the finest raw materials, ranging from sturdy metals like aluminium and stainless steel to versatile plastics and composites.

Digital Blueprinting

Every masterpiece starts with a blueprint. Using cutting-edge Computer-Aided Design (CAD) software, engineers translate visions into digital realities, providing meticulous instructions for the CNC milling machines.

Tool Tactics

With the blueprint in hand, the next step involves selecting the perfect arsenal of cutting tools. From end mills to face mills, each tool is chosen with precision, tailored to sculpt the material into desired forms.

Machine Marvels

As the stage is set, the CNC milling machine springs into action. With the material securely clamped, the machine follows the digital blueprint, orchestrating a symphony of movements along multiple axes.

Precision Carving

The cutting tools move across the material, sculpting intricate shapes and contours with surgical precision. From rough cuts to fine finishes, each movement is meticulously orchestrated to perfection.

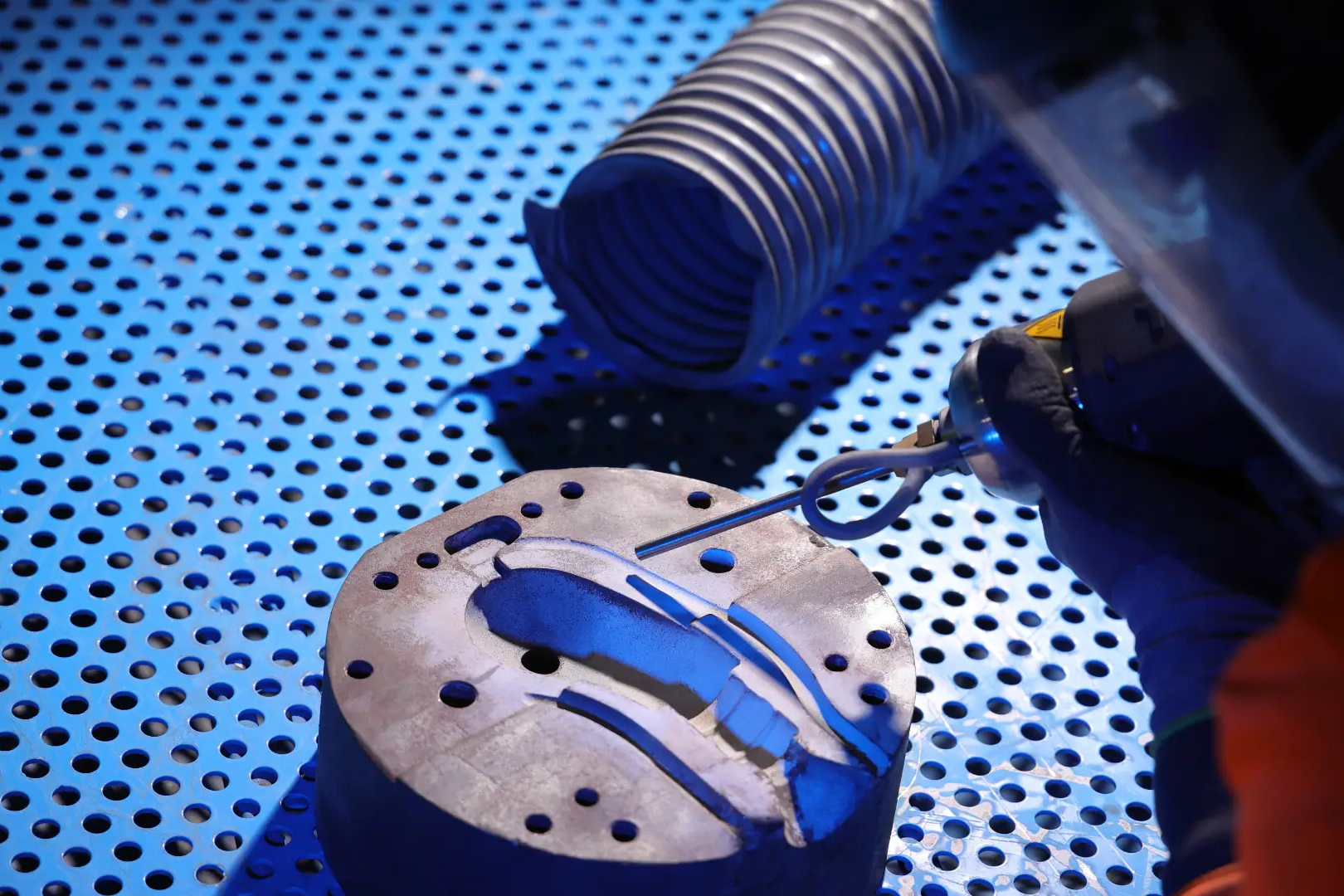

Finishing Flourishes

As the masterpiece nears completion, finer tools may be summoned to add exquisite details and surface finishes, ensuring that every component meets the highest standards of craftsmanship.

Quality

Throughout the process, vigilant eyes oversee every detail, ensuring that each component emerges with flawless precision. Advanced measuring equipment guarantees dimensional accuracy and surface perfection.

In the realm of CNC Turning, Copamate’s expertise shines bright, delivering precision components with unmatched efficiency. Here’s a glimpse into the artistry of CNC turning

Material Options

Like a painter’s palette, a diverse array of materials awaits transformation. From metals to plastics, each material holds the promise of sculpted perfection.

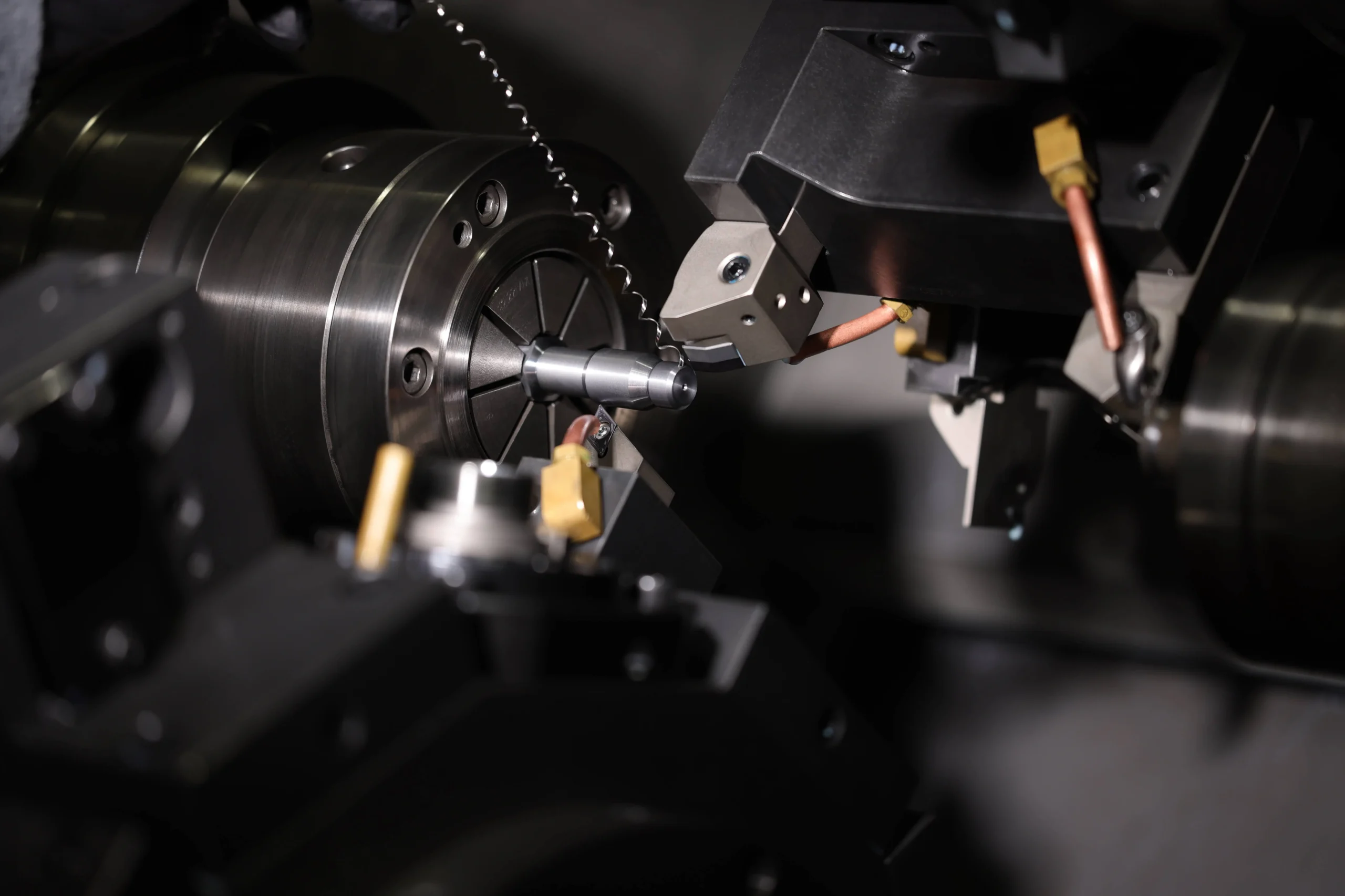

Chuck

The raw material, cradled within the chuck of the CNC lathe, awaits its moment of transformation. With unwavering stability, it prepares for the journey ahead.

Cutting Tools

Armed with an arsenal of cutting tools, the lathe stands ready to sculpt raw materials into refined forms. From turning tools to drills, each tool plays a vital role in the symphony of creation.

Programmed Precision

With digital precision, the CNC lathe executes its choreographed movements. Guided by digital blueprints, it breathes life into raw materials, shaping them into works of art.

Carving

As the workpiece rotates, the cutting tools spring into action, carving intricate profiles with effortless grace. From rough passes to final contours, each movement is a testament to precision engineering.

Masterful Machining

With unyielding precision, the CNC lathe navigates the complexities of turning, delivering components with unrivalled accuracy. Dimensional tolerances are met with surgical precision, ensuring perfection at every turn.

Perfection Pursuit

At the journey’s end, each component undergoes meticulous inspection, ensuring that it meets the exacting standards of Bredo’s craftsmanship. From flawless finishes to precise dimensions, excellence reigns supreme.

CNC milling and turning stand as beacons of innovation and precision in the manufacturing landscape. With Bredo’s unwavering commitment to excellence, these processes continue to shape the future of industry, one precision component at a time. Join us on this journey of precision CNC engineering and possibility, where craftsmanship knows no bounds. Contact us

Related Posts

June 3, 2024

What is Cold Spray? | Comprehensive Overview

What is cold spray? Cold spray is an advanced coating and additive…

June 2, 2024

17 CNC Machining Materials | Comprehensive Guide

Selecting the right CNC machining materials material is crucial to the success…

June 1, 2024

CNC Machining Tolerances | Comprehensive Guide

CNC machining tolerances are essential for achieving the desired precision and…