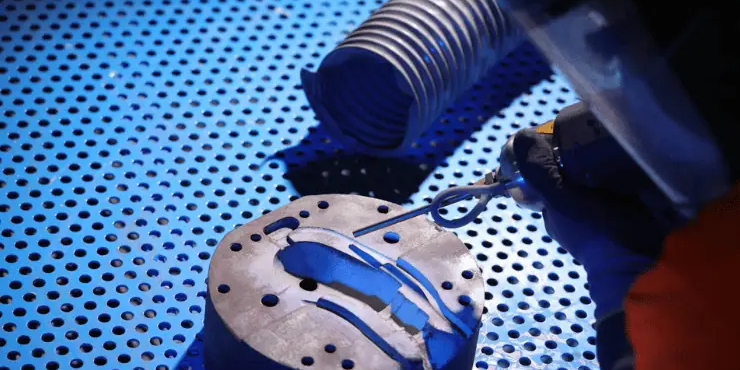

Tooling Repair, Metal Patching, Warranty Repairs, and More

At Bredo, we’re your trusted partner in tool repair. We have experience in repairing parts of all sizes and brands. Plus, with our experience working with major brands and genuine parts, we’re trusted by a vast number of industries across Australia and internationally.

Whether you need lathe refurbishment, shaft repair, jig repair, or reconditioned tools, we can help. When you’re looking for experienced service agents with competitive pricing, bring your engineered repair projects to us.

Our Tool Repairs

We provide a wide range of options for tooling repairs. These include:

- Metal patching

- Refurbished tools

- Precision repairs

- Shaft repair

- Reconditioned tools

- Warranty repairs

- Jig repair

- Coating capabilities

- Genuine parts

- Lathe refurbishment

- Digital cold spray services

Materials We Repair

As service agents who work with many major brands, we’re committed to high-quality tool repairs. We work with:

- Plastics

- Bronze

- Copper

- Silver Steel

- Magnesium

- Cast Iron

- Macor Ceramics

- Green Carbide

- Inconel 625 (HE)

- Aluminium

- Zinc

- Glass

- Tin

- Nickel

- Babbit

- Gold

- Silver

- Platinum

Your Tool Repair Questions Answered

We restore, repair, and rebuild worn or damaged shafts for businesses of all sizes. Our shaft repair service ensures your tools and equipment operate well for as long as possible. Our shaft restoration, repairing, and rebuilding capabilities include:

-

- Driveshafts

- Proshafts

- CV boots

- Universal joints

- CV joints

- Tailshafts

- Pumps

- Boxes

- Power steering racks

And more.

We provide digital cold spray services with our Titomic D523 Standard Low-Pressure Cold Spray System. This equipment allows us to repair various materials such as glass, metal, and casting plastics with precision. This includes corrosion protection, electrical conductivity, and hermetic sealing.

We perform tool repairs for a wide range of industries in the manufacturing and engineering sectors including automotive, air, rail, defence, and more.

We conduct regular quality inspections during our processes to ensure high standards. As part of our dedication to precision, we ensure accuracy of:

- ±0.127 mm (±0.005 in.)

- ±0.0015 mm/mm (±0.0015 in/in)

Expertise

We have years of experience in warranty repairs, tool service, and more across many brands.

Genuine Parts

We use genuine parts for every job to ensure reliable repairs.

Competitive Pricing

We aim to make quality repairs accessible to all customers.

Accreditations

Utilising ISO 9001:2015 we guarantee quality solutions for required parts.

Contact Us to Service Your Purchase

Ensuring minimal downtime is of great importance to you. As such, we provide efficient tooling repairs so you can get back on the job quickly. With fully trained warranty agents working on your equipment, tool repair is a simple and easy process. To get started, contact us at Bredo today.