Bredo is your go-to destination for high quality additive manufacturing solutions designed to meet your business requirements. With cutting-edge technologies and a skilled team, we offer a comprehensive range of 3D printing and digital cold spray services to revolutionise your manufacturing processes.

High-Accuracy 3D Printing with Stratasys Fortus 450mc

At Bredo, we make use of the Stratasys Fortus 450mc, a high-precision 3D printing technology that allows us to create parts of any size with accuracy and efficiency. Whether you need simple or complex 3D printed components, our advanced 3D printing capabilities can bring your concepts to life.

- Streamlined Manufacturing: Our 3D printing technology, located in Melbourne, Australia, streamlines manufacturing processes and reduces production costs, offering unparalleled efficiency for your projects.

- Durable Materials: We utilise production-grade thermoplastics to produce durable parts suitable for various industries, including defence, automotive, aerospace, rail, and commercial sectors.

- Large-Scale Production: With the capability to produce large quantities of manufactured parts for prototyping potential components, we offer cost-effective solutions without compromising quality.

Versatile Materials and Superior Accuracy

Bredo offers a diverse range of materials for 3D printing, including ABS-M30, ASA, ABS-ESD7, PC-ABS, PC, PC-ISO, Nylon12, and more. Our advanced additive manufacturing processes ensure exceptional accuracy with tolerances as low as ± . 127 mm (± . 005 in.) or ± . 0015 mm/mm (± .

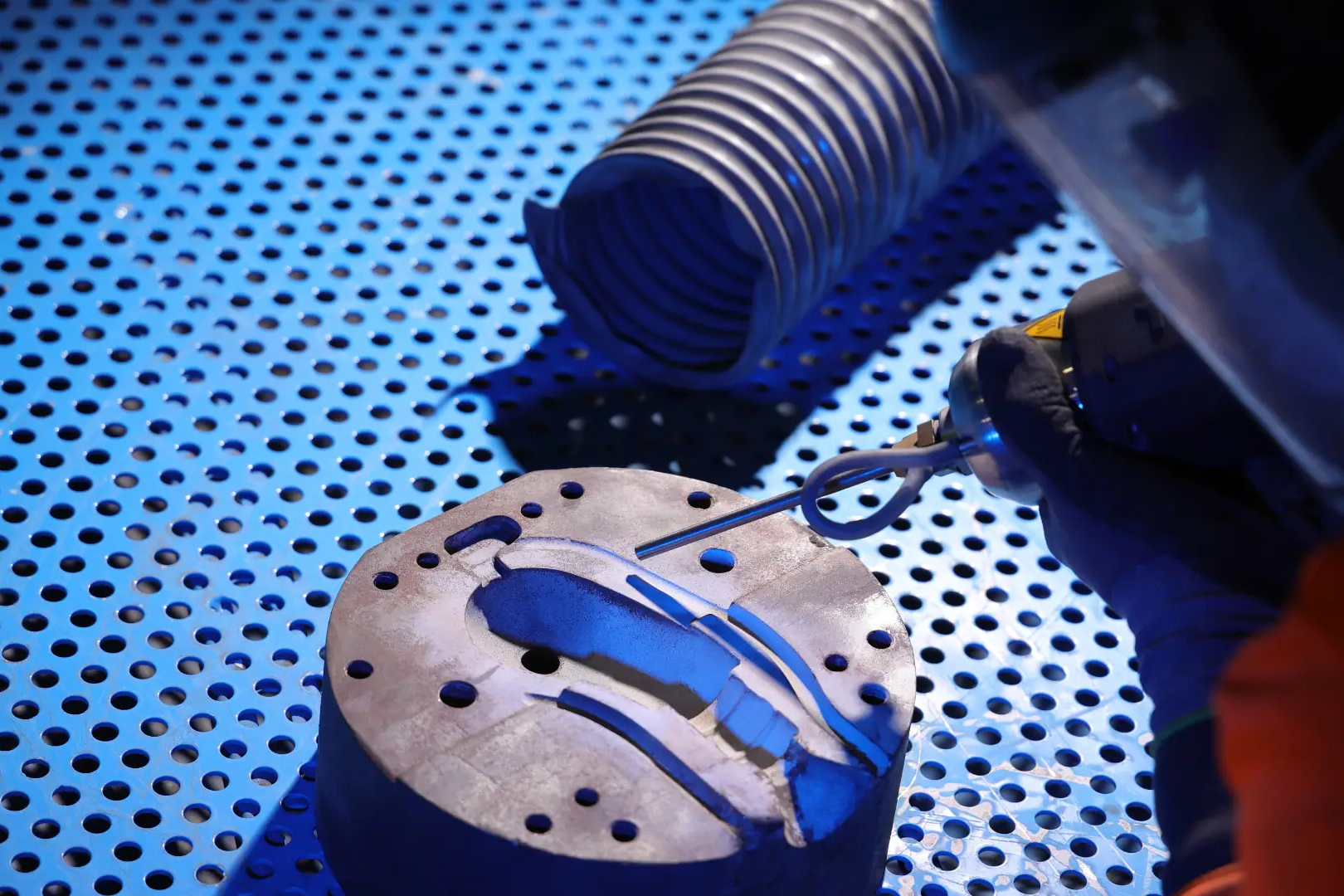

Innovative Digital Cold Spray Technology

In addition to 3D printing, Bredo utilises the Titomic D523 Standard Low-Pressure Cold Spray System for digital cold spray applications. This cutting-edge technology allows us to repair glass, metal, and casting plastics without the need for heat.

- Cost-Effective Solutions: Our cold spray system delivers cost-effective digital manufacturing solutions by creating high-performance metal coatings for your products, ensuring durability and longevity.

- Precision Repairs: With the ability to repair corrosive damage, defects in cylinder parts, and add electrically conductive layers to materials, our cold spray system offers precision repairs without distortion or oxidation.

- Versatile Applications: The Titomic D523 Cold Spray System can fuse dissimilar metals, including aluminium, zinc, copper, tin, nickel, and more, to create custom solutions for your projects.

Bredo is dedicated to providing advanced additive manufacturing and digital cold spray solutions that cater to the evolving needs of your business. With our cutting-edge technologies and expertise, we empower you to innovate, accelerate production, and achieve excellence in every project.

Contact our team today to explore how Bredo can transform your manufacturing processes with our advanced solutions.

Related Posts

June 3, 2024

What is Cold Spray? | Comprehensive Overview

What is cold spray? Cold spray is an advanced coating and additive…

June 2, 2024

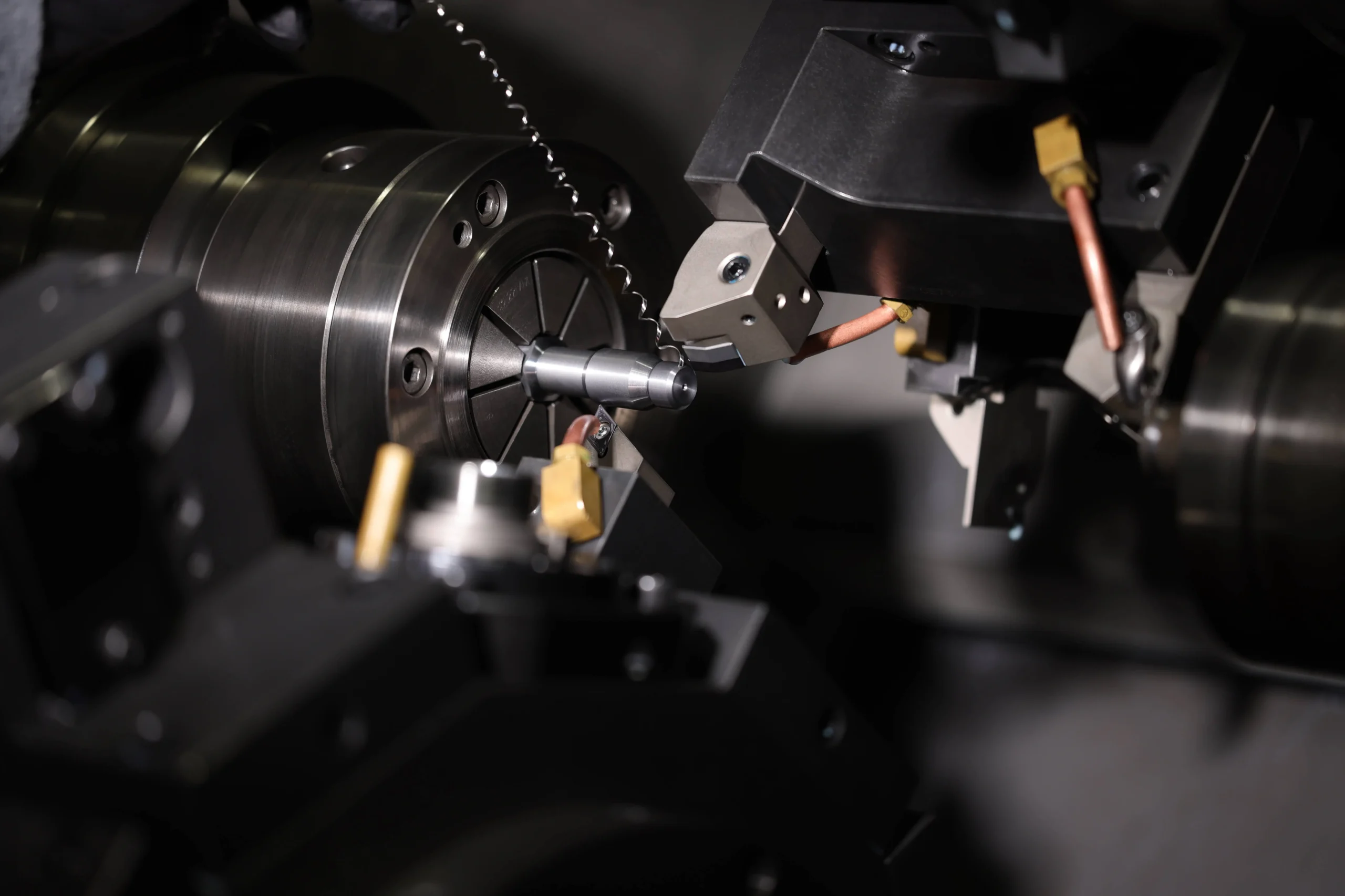

17 CNC Machining Materials | Comprehensive Guide

Selecting the right CNC machining materials material is crucial to the success…

June 1, 2024

CNC Machining Tolerances | Comprehensive Guide

CNC machining tolerances are essential for achieving the desired precision and…