In the dynamic landscape of manufacturing, adhering to international standards is paramount to ensuring quality, safety, and efficiency across various industries. Among the myriad of standards, ISO certifications stand out as benchmarks of excellence, providing organisations with a framework to achieve operational excellence and meet customer expectations. Join us on a journey through the realm of ISO certifications, exploring their significance, nuances, and the pivotal role they play in shaping manufacturing practices.

What are ISO Certifications?

ISO certifications are internationally recognized standards developed by the International Organisation for Standardisation (ISO) that establish criteria for quality, safety, environmental management, and other key aspects of business operations. These certifications help organisations demonstrate their commitment to excellence, enhance customer confidence, and access new markets by adhering to globally accepted best practices.

ISO 27001: Information Security Management Systems (ISMS)

ISO 27001 sets forth requirements for establishing, implementing, maintaining, and continually improving an Information Security Management System (ISMS). This standard is particularly crucial for manufacturing industries, especially in Defence, where sensitive information and classified data must be securely managed to safeguard national security interests.

In the Defence sector, ISO 27001 plays a pivotal role in ensuring the confidentiality, integrity, and availability of information assets critical to national defence strategies. By implementing ISO 27001-compliant ISMS, Defence organisations can mitigate the risk of cyber threats, unauthorised access, and data breaches, thus safeguarding classified information and maintaining operational readiness.

ISO 9001: Quality Management Systems (QMS)

ISO 9001 is the cornerstone of quality management, outlining principles and requirements for establishing a robust Quality Management System (QMS). By achieving ISO 9001 certification, organisations demonstrate their ability to consistently provide products and services that meet customer requirements and comply with applicable regulations.

In the context of Australian manufacturing, ISO 9001 certification holds significant importance. It provides a framework for Australian manufacturers to streamline their processes, improve efficiency, and enhance product quality. By adhering to ISO 9001 standards, manufacturers can gain a competitive edge in both domestic and international markets, as ISO 9001 certification is often a prerequisite for supplier qualification and can enhance the credibility and reputation of Australian-made products.

Additionally, ISO 9001 certification fosters a culture of continuous improvement within manufacturing organisations, driving innovation, reducing waste, and increasing customer satisfaction. Overall, ISO 9001 plays a crucial role in elevating the quality and competitiveness of Australian manufacturing on the global stage.

ISO 14001: Environmental Management Systems (EMS)

ISO 14001 sets standards for Environmental Management Systems (EMS), enabling organisations to identify, monitor, and control their environmental impact. By implementing ISO 14001, organisations can reduce waste, conserve resources, and enhance their environmental performance while complying with regulatory requirements. In the realm of Australian manufacturing, ISO 14001 certification holds immense significance.

It provides manufacturers with a structured approach to environmental management, helping them mitigate risks, minimise environmental liabilities, and demonstrate their commitment to sustainability. By adhering to ISO 14001 standards, Australian manufacturers can improve their environmental stewardship, reduce their carbon footprint, and contribute to the preservation of natural resources and ecosystems.

Additionally, ISO 14001 certification can enhance the reputation of Australian manufacturing companies, both domestically and internationally, by signalling their dedication to environmental responsibility and corporate citizenship. Ultimately, ISO 14001 empowers Australian manufacturers to achieve operational excellence while safeguarding the environment for future generations.

ISO 45001: Occupational Health and Safety Management Systems (OHSMS)

ISO 45001 establishes requirements for Occupational Health and Safety Management Systems (OHSMS), helping organisations create safe and healthy workplaces for employees and stakeholders. By adhering to ISO 45001, organisations can minimise occupational hazards, prevent work-related injuries and illnesses, and foster a culture of safety. In the context of Australian manufacturing, ISO 45001 certification holds paramount importance.

It provides manufacturers with a structured framework to identify, assess, and control occupational health and safety risks, ensuring the well-being of their workforce and enhancing productivity. By implementing ISO 45001 standards, Australian manufacturers can demonstrate their commitment to employee health and safety, comply with regulatory requirements, and mitigate the financial and reputational risks associated with workplace accidents and injuries. Moreover, ISO 45001 certification can help manufacturers attract and retain talent, as employees are more likely to be attracted to organisations that prioritise their health and safety.

ISO 13485: Medical Devices - Quality Management Systems

ISO 13485 is a quality management standard specific to the medical device industry, outlining requirements for the design, development, production, and servicing of medical devices. By achieving ISO 13485 certification, organisations demonstrate their commitment to ensuring the safety and efficacy of medical devices and complying with regulatory requirements. In the context of Australian manufacturing, ISO 13485 certification is particularly significant for companies operating in the medical device sector. It provides manufacturers with a framework to establish and maintain stringent quality management practices throughout the product life cycle, from initial design to post-market surveillance.

By adhering to ISO 13485 standards, Australian medical device manufacturers can enhance product quality, reliability, and safety, thus instilling confidence in healthcare professionals and patients alike. ISO 13485 certification also facilitates market access, as regulatory bodies and healthcare institutions often require compliance with ISO 13485 as a prerequisite for product approval and procurement. Additionally, ISO 13485 certification fosters a culture of continuous improvement within medical device companies, driving innovation, reducing risk, and ultimately improving patient outcomes.

Overall, ISO 13485 plays a critical role in ensuring the integrity and efficacy of medical devices manufactured in Australia, contributing to the advancement of healthcare and patient well-being.

ISO 19650: Building Information Modelling (BIM)

ISO 19650 provides guidelines for the management of information throughout the life cycle of built assets using Building Information Modelling (BIM) methodology. By adopting ISO 19650, organisations in the construction industry can streamline collaboration, improve project outcomes, and optimise asset performance. In the context of Australian construction and infrastructure development, ISO 19650 certification holds significant relevance.

It offers a standardised approach to information management, facilitating seamless communication and coordination among project stakeholders, including architects, engineers, contractors, and facility managers.

By adhering to ISO 19650 standards, Australian construction companies can enhance project efficiency, reduce errors and rework, and deliver projects on time and within budget. ISO 19650 also promotes interoperability and data exchange between different software platforms, enabling greater integration and efficiency in project delivery. Moreover, ISO 19650 certification enhances transparency and accountability in the construction process, as it requires clear documentation and traceability of information from conception to decommissioning of built assets. Ultimately, ISO 19650 empowers Australian construction organisations to embrace digital transformation, improve project delivery practices, and deliver high-quality, sustainable built environments that meet the evolving needs of society.

ISO 55001: Asset Management

ISO 55001 sets standards for Asset Management Systems (AMS), helping organisations manage their assets effectively to achieve their strategic objectives. By implementing ISO 55001, organisations can optimise asset performance, minimise risks, and maximise return on investment.

In the context of Australian industries, including manufacturing, utilities, transportation, and infrastructure, ISO 55001 certification holds significant importance. It provides a structured framework for organisations to manage their assets throughout their lifecycle, from acquisition to disposal, ensuring alignment with strategic goals and operational requirements.

By adhering to ISO 55001 standards, Australian organisations can enhance asset reliability, availability, and maintainability, thus improving operational efficiency and reducing downtime. ISO 55001 also facilitates risk-based decision-making, enabling organisations to identify and mitigate asset-related risks while maximising opportunities for value creation. Moreover, ISO 55001 certification fosters a culture of continuous improvement within organisations, driving innovation, cost savings, and sustainable asset management practices. Overall, ISO 55001 empowers Australian industries to unlock the full potential of their assets, drive business growth, and achieve long-term success in a competitive global marketplace.

ISO 26000: Social Responsibility

ISO 26000 provides guidance on social responsibility, outlining principles and practices for organisations to contribute to sustainable development and address societal issues. By adhering to ISO 26000, organisations can enhance their reputation, build trust with stakeholders, and contribute positively to society.

By aligning with ISO 26000 standards, Australian organisations can demonstrate their commitment to ethical conduct, fair labour practices, environmental stewardship, and community engagement. ISO 26000 certification also fosters collaboration and dialogue with stakeholders, including employees, customers, suppliers, and local communities, to address social and environmental challenges collectively.

In the context of Australian businesses across various sectors, including manufacturing, services, and corporate entities, ISO 26000 certification holds substantial significance. It offers a framework for organisations to integrate social responsibility into their core business operations and decision-making processes, thereby promoting ethical practices, transparency, and accountability.

Moreover, ISO 26000 helps Australian businesses enhance their brand reputation, attract socially-conscious consumers and investors, and differentiate themselves in the marketplace. Ultimately, ISO 26000 empowers Australian organisations to create shared value, foster sustainable development, and contribute to the well-being of society at large.

ISO 31000: Risk Management

ISO 31000 offers principles, framework, and guidelines for risk management, helping organisations identify, assess, and mitigate risks effectively. By adopting ISO 31000, organisations can enhance decision-making, improve resilience, and create value while managing uncertainty. In the context of Australian businesses across diverse industries, including manufacturing, finance, healthcare, and energy, ISO 31000 certification plays a crucial role in strengthening risk management practices.

It provides organisations with a systematic approach to understanding and addressing risks inherent in their operations, projects, and strategic initiatives. By adhering to ISO 31000 standards, Australian organisations can proactively identify potential threats, assess their potential impact, and implement appropriate risk mitigation measures.

ISO 31000 also fosters a culture of risk awareness and accountability within organisations, promoting a proactive approach to risk management at all levels. Moreover, ISO 31000 certification helps Australian businesses enhance their resilience to unexpected events, adapt to changing market conditions, and seize opportunities for growth and innovation. Ultimately, ISO 31000 empowers Australian organisations to navigate uncertainty confidently, make informed decisions, and achieve their objectives in an ever-changing business landscape.

The Importance of ISO Accreditation

ISO accreditation is a testament to an organisation’s commitment to excellence, demonstrating compliance with internationally recognized standards and best practices. By obtaining ISO certification, organisations can enhance their credibility, competitiveness, and market access while driving continuous improvement and customer satisfaction.

How to Obtain ISO Certification

Obtaining ISO certification involves several key steps:

- Assessment – Assess your organisation’s readiness and identify gaps in compliance with ISO standards.

- Planning – Develop a comprehensive plan to address identified gaps and implement necessary changes to meet ISO requirements.

- Documentation – Prepare documentation, including policies, procedures, and records, to demonstrate compliance with ISO standards.

- Training – Provide training and awareness programs to ensure employees understand their roles and responsibilities in implementing ISO standards.

- Audit – Undergo a formal audit or assessment by an accredited certification body to verify compliance with ISO standards.

- Certification – Upon successful completion of the audit, obtain ISO certification, which validates your organisation’s adherence to internationally recognized standards and best practices.

Certifications

ISO certifications play a pivotal role in driving excellence and innovation in manufacturing. By adhering to internationally recognized standards and obtaining ISO certification, organisations can enhance their operational efficiency, mitigate risks, and improve customer satisfaction. Whether it’s ensuring the quality of products, safeguarding information security, or promoting environmental sustainability, ISO certifications empower manufacturers to achieve their goals and thrive in an increasingly competitive global marketplace. Check AS Standards

Ready to elevate your manufacturing excellence with ISO certifications? Contact us today to explore our comprehensive range of certification services and unlock the full potential of ISO standards in your manufacturing operations.

Related Posts

June 3, 2024

What is Cold Spray? | Comprehensive Overview

What is cold spray? Cold spray is an advanced coating and additive…

June 2, 2024

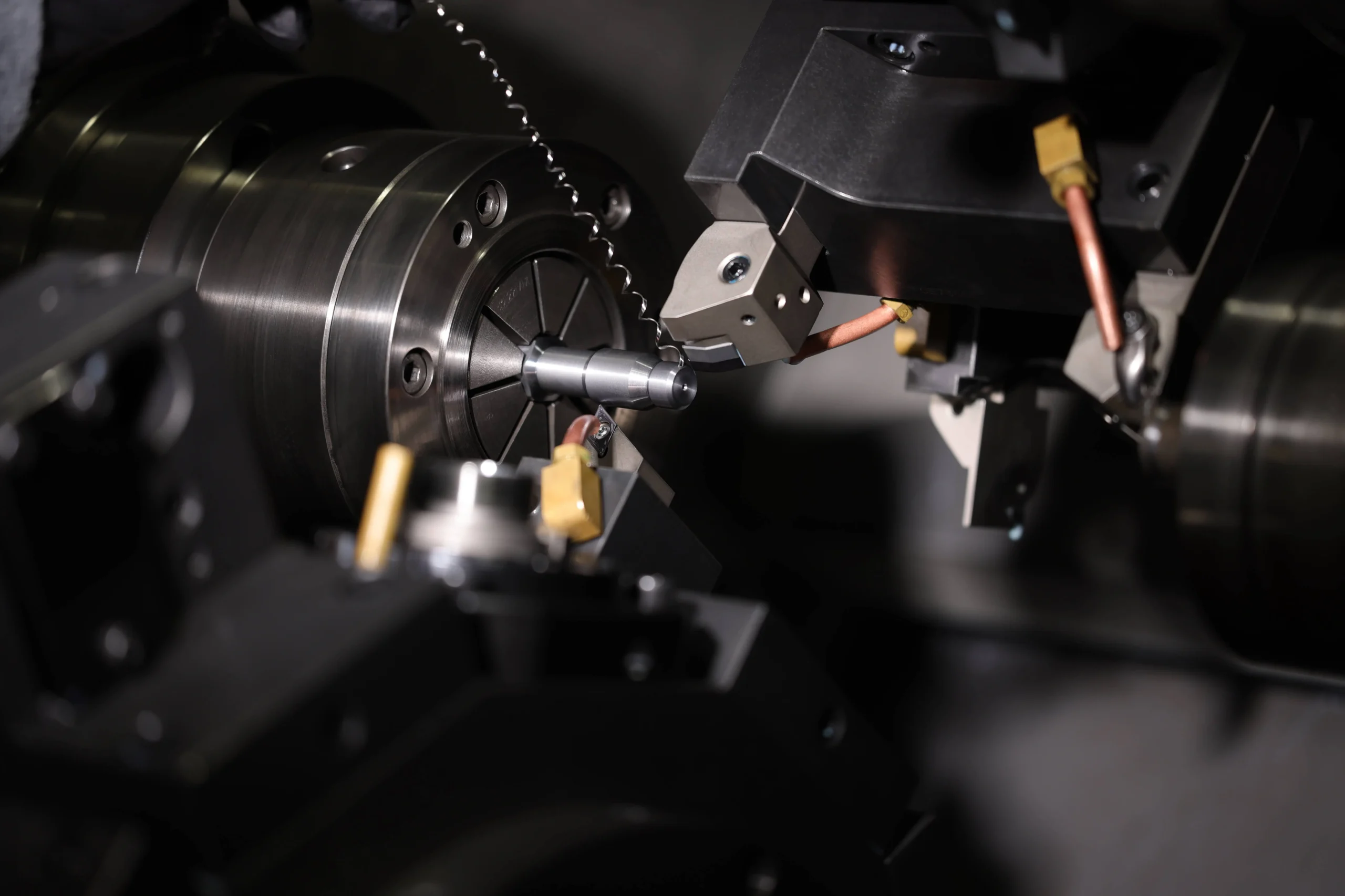

17 CNC Machining Materials | Comprehensive Guide

Selecting the right CNC machining materials material is crucial to the success…

June 1, 2024

CNC Machining Tolerances | Comprehensive Guide

CNC machining tolerances are essential for achieving the desired precision and…