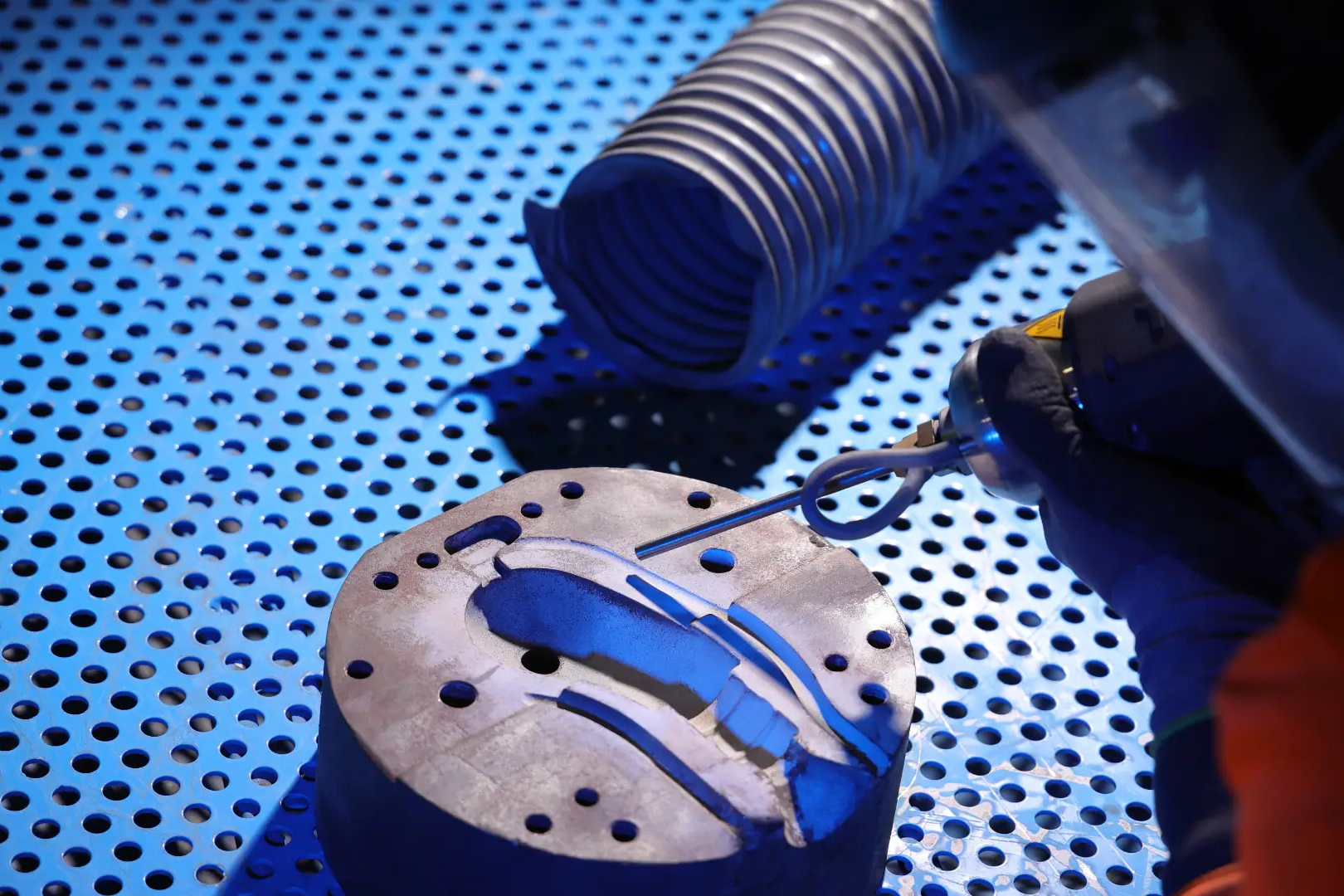

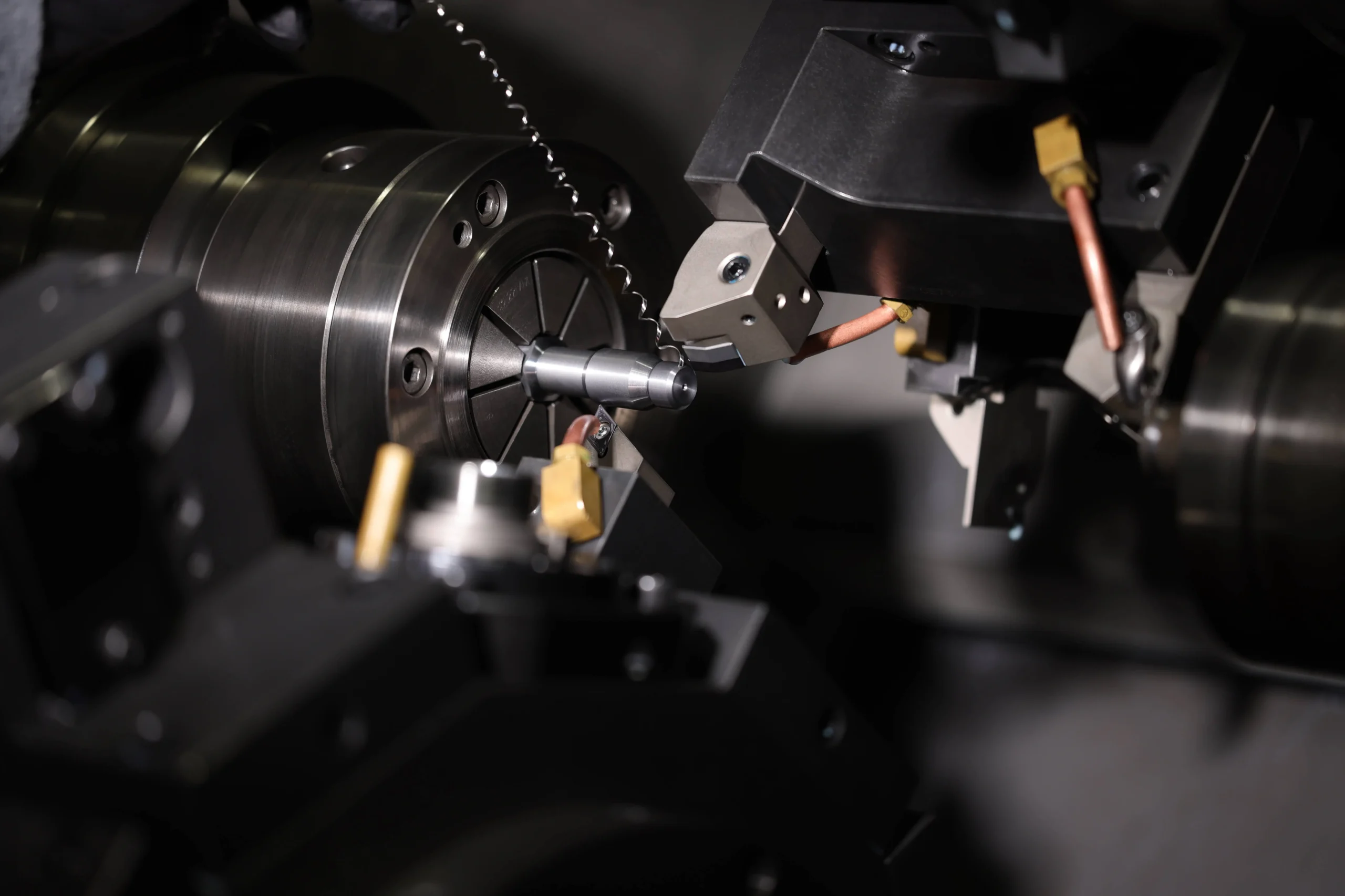

CNC (Computer Numerical Control) machines have revolutionised the manufacturing landscape, offering unparalleled precision, efficiency, and versatility. They are utilised across a broad spectrum of industries to create intricate and high-quality parts. This blog delves into what can CNC machines manufacture, highlighting their applications and benefits.

What Can CNC Machines Manufacture?

Clevis Machining

Clevises are essential components used in mechanical linkages, often found in machinery and structural applications. CNC machines ensure that these parts are machined to precise specifications, ensuring strength and durability. This precision is crucial for applications that demand high load-bearing capacity and reliability. The aerospace and automotive industries, in particular, benefit from the accuracy of CNC machining for clevis parts, ensuring safety and performance in critical operations.

Automotive Parts

The automotive industry relies heavily on CNC machining for the production of various components. CNC machines are used to manufacture engine parts, transmission components, and suspension systems. The precision offered by CNC machining ensures that these parts fit perfectly and function efficiently, which is vital for the safety and performance of vehicles. CNC machining also allows for the creation of complex geometries that are often required in modern automotive designs, such as intricate engine blocks and transmission cases.

Aerospace Parts

In the aerospace sector, the need for precision and reliability is paramount. CNC machines produce critical components such as turbine blades, structural airframe parts, and engine components. These parts must adhere to strict tolerances and material standards to withstand extreme conditions and stresses encountered during flight. CNC machining allows for the use of high-performance materials like titanium and composites, which are essential for aerospace applications due to their strength-to-weight ratios.

Defence Parts

CNC machining plays a critical role in the defence industry, producing parts for firearms, military vehicles, and aircraft. The precision and consistency of CNC machines are essential for ensuring the reliability and performance of defence equipment. Components like weapon receivers, barrel assemblies, and missile components are commonly manufactured using CNC technology. The ability to produce parts that meet stringent military standards and specifications makes CNC machining indispensable for defence manufacturing.

Medical Parts

The medical industry benefits greatly from CNC machining, especially for producing surgical instruments, implants, and prosthetics. The ability to machine biocompatible materials like titanium and stainless steel with high precision ensures that medical parts meet stringent health and safety standards. Custom implants and dental prosthetics are also frequently made using CNC machines. These devices must be precisely tailored to individual patients, which CNC technology facilitates by allowing for highly detailed and customisable machining.

Car Badges

CNC machining is used to create custom car badges, which are an important branding element for automotive manufacturers. These badges require intricate designs and must be durable enough to withstand various environmental conditions. CNC machines can produce these badges with detailed precision and high-quality finishes. The ability to replicate complex logos and designs consistently makes CNC machining ideal for producing high-end car badges.

Custom Engravings

Custom engravings on metals, plastics, and other materials are easily achieved with CNC machining. This is particularly useful for creating personalised items such as jewellery, awards, and promotional products. The precision of CNC machines ensures that even the most intricate designs are accurately reproduced. CNC engraving is also widely used in industrial applications, such as marking parts with serial numbers or barcodes for traceability.

Bike Pedals

Bike pedals, especially those designed for high-performance and competitive cycling, are often manufactured using CNC machining. These components require a combination of strength, lightweight, and precision to enhance the performance and safety of the bicycle. CNC machining allows for the use of advanced materials and designs that improve the ergonomics and functionality of bike pedals, catering to both casual cyclists and professional athletes.

Whistles

Precision is essential in the manufacturing of whistles to ensure the correct pitch and functionality. CNC machines are used to create whistles from various materials, including metal and plastic, ensuring that each piece is uniform and meets quality standards. The ability to produce intricate internal shapes and fine-tune the acoustic properties of whistles makes CNC machining the preferred method for high-quality whistle production.

Electronics

The electronics industry uses CNC machining to produce parts such as heat sinks, enclosures, and connectors. These components must be manufactured with high precision to ensure they fit correctly and function as intended in electronic devices. CNC machining allows for the production of complex shapes and fine details required in electronic components. This precision ensures that electronic devices operate reliably and efficiently, meeting the demands of modern technology.

Electronics

The electronics industry uses CNC machining to produce parts such as heat sinks, enclosures, and connectors. These components must be manufactured with high precision to ensure they fit correctly and function as intended in electronic devices. CNC machining allows for the production of complex shapes and fine details required in electronic components. This precision ensures that electronic devices operate reliably and efficiently, meeting the demands of modern technology.

Satellite Parts

The aerospace industry, including satellite manufacturing, relies on CNC machining for producing components that require extreme precision. Parts such as satellite frames, brackets, and antenna mounts are made using CNC machines to ensure they meet the rigorous standards necessary for space applications. The ability to work with advanced materials like titanium and carbon composites, combined with the precision of CNC machining, ensures that satellite parts are both lightweight and robust.

Transportation

CNC machines are used to produce a variety of tools, including cutting tools, moulds, and dies. The precision and durability of CNC-machined tools are essential for maintaining the quality and efficiency of various manufacturing processes. Custom tools tailored to specific applications can also be produced using CNC machining. This capability ensures that tools meet the exact requirements of different industrial processes, enhancing productivity and product quality.

Tools

Beyond automotive and aerospace, CNC machining is used in other transportation sectors, including railway and marine. Components such as engine parts, structural elements, and interior fittings are manufactured with high precision to ensure safety, reliability, and performance. CNC machining allows for the production of complex shapes and the use of high-strength materials, which are essential for modern transportation solutions.

Conclusion

At Bredo, we specialise in CNC machining services, providing high-quality and precise components for a variety of industries. Whether you need custom parts, prototypes, or large-scale production, our state-of-the-art CNC machines and experienced team are here to meet your needs. Contact us today to learn more about our services and how we can help with your next project.

CNC machining is a versatile and essential technology in modern manufacturing, capable of producing a wide range of products with high precision and efficiency. From automotive and aerospace parts to custom engravings and medical devices, CNC machines play a critical role in ensuring the quality and performance of these components. As technology continues to advance, the capabilities of CNC machining will only expand, further solidifying its importance in various industries.

Related Posts

June 3, 2024

What is Cold Spray? | Comprehensive Overview

What is cold spray? Cold spray is an advanced coating and additive…

June 2, 2024

17 CNC Machining Materials | Comprehensive Guide

Selecting the right CNC machining materials material is crucial to the success…

June 1, 2024

CNC Machining Tolerances | Comprehensive Guide

CNC machining tolerances are essential for achieving the desired precision and…