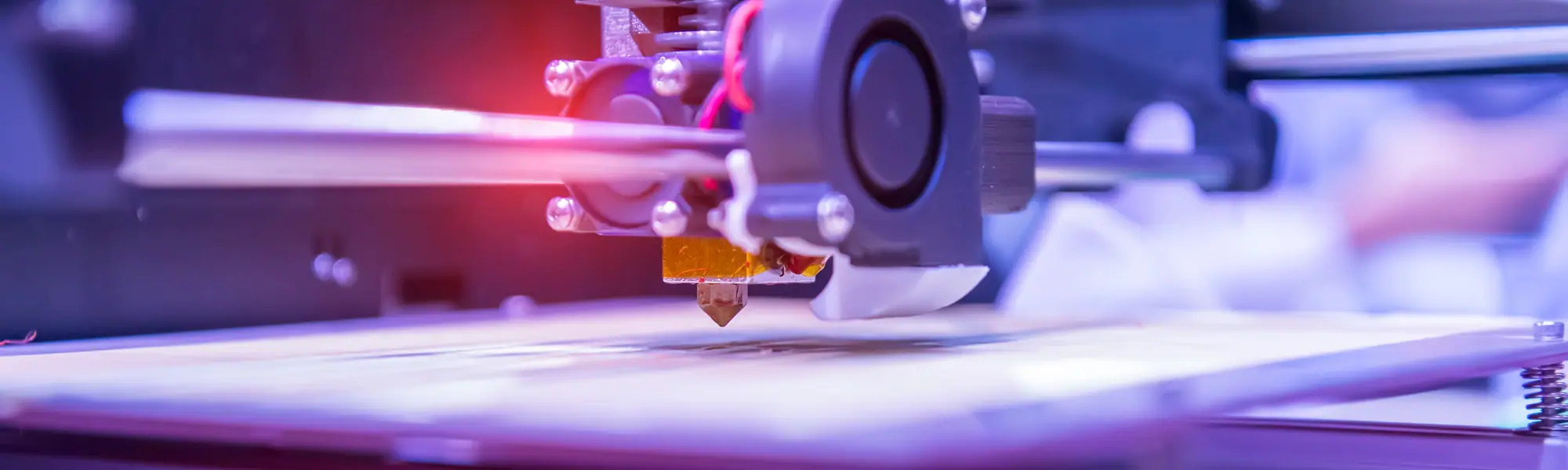

In today’s fast-paced manufacturing landscape, additive manufacturing, commonly known as 3D printing, has emerged as a game-changer. Offering unparalleled design freedom, rapid prototyping capabilities, and cost-effective production solutions, 3D printing has revolutionised traditional manufacturing methods. Let’s delve deeper into the various types of 3D printing processes, their applications, and the advantages they offer to industries worldwide.

What is 3D Printing?

At its core, 3D printing is an additive manufacturing process that builds three-dimensional objects layer by layer from digital models. Unlike subtractive manufacturing techniques, which involve removing material from a solid block, 3D printing adds material precisely where needed, resulting in minimal waste and maximum efficiency. This versatility enables designers and engineers to create complex geometries and intricate designs that were once impossible to achieve using traditional methods.

Rapid Prototyping

One of the key advantages of 3D printing is its ability to facilitate rapid prototyping. By quickly producing physical prototypes from digital designs, designers and engineers can iterate on their concepts, test functionality, and gather feedback early in the development process. This accelerated iteration cycle reduces time to market and enables faster innovation, giving companies a competitive edge in today’s dynamic marketplace.

Five 3D Printing Considerations

Before embarking on a 3D printing project, it’s essential to consider several factors:

Material Compatibility

Different 3D printing processes are compatible with specific materials, ranging from polymers and metals to ceramics and composites.

Print Resolution

The level of detail and precision required for the final part will dictate the optimal print resolution.

Build Volume

The size of the build volume determines the maximum dimensions of the printed part.

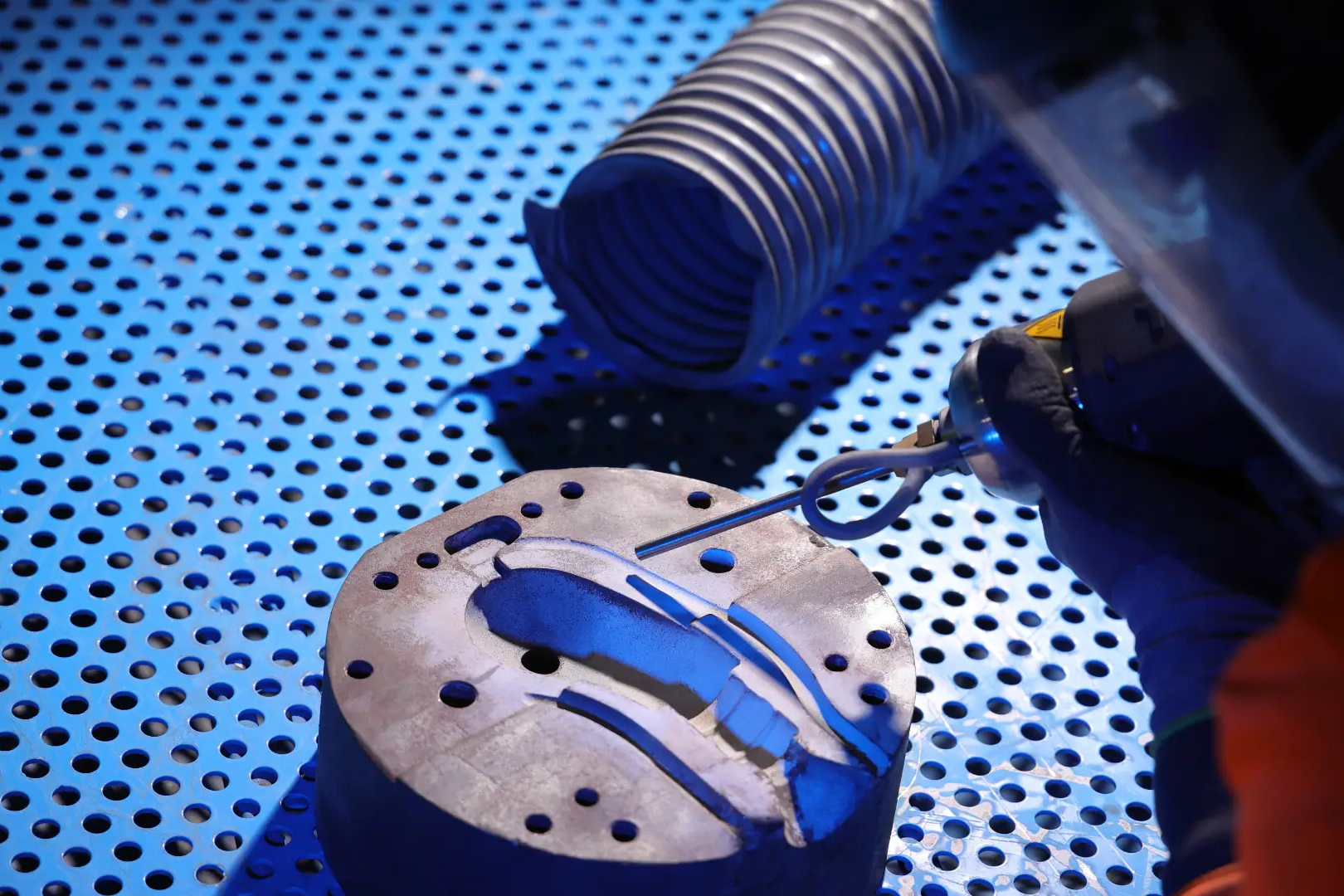

Post-Processing Requirements

Depending on the printing process and material used, post-processing steps such as cleaning, curing, and finishing may be necessary.

Cost and Scalability

Understanding the cost implications and scalability of 3D printing is crucial for determining its feasibility for production.

Types of 3D Printing

The types of 3D printing consist of:

Polymer 3D Printing Processes

Polymer-based 3D printing processes offer a wide range of options for creating functional prototypes and end-use parts. Let’s explore some of the most commonly used techniques:

Stereolithography (SLA)

SLA utilises a UV laser to cure liquid photopolymer resin layer by layer, resulting in high-resolution parts with smooth surface finishes. It’s ideal for applications requiring intricate details and fine features, such as jewellery, dental models, and concept models.

Selective Laser Sintering (SLS)

SLS employs a high-powered laser to sinter powdered material, typically nylon or other thermoplastics, into solid layers. This process offers excellent strength, durability, and material properties, making it suitable for functional prototypes, end-use parts, and low-volume production runs.

Fused Deposition Modelling (FDM)

FDM extrudes thermoplastic filament layer by layer, making it one of the most widely used 3D printing processes. It’s affordable, versatile, and suitable for a wide range of applications, from rapid prototyping to manufacturing tooling and production parts.

PolyJet

PolyJet utilises inkjet technology to jet layers of liquid photopolymer onto a build platform, allowing for multi-material and multi-color printing with high accuracy and detail. It’s perfect for creating realistic prototypes, product mock-ups, and architectural models with vibrant colours and textures.

Digital Light Processing (DLP)

DLP employs a digital light projector to cure liquid photopolymer resin layer by layer, offering fast print speeds and high resolution. It’s ideal for applications requiring high throughput and detailed parts, such as dental models, medical devices, and consumer electronics.

Multi Jet Fusion (MJF)

MJF utilises a multi-agent printing process to selectively fuse powdered material with an inkjet array, enabling fast production speeds and excellent dimensional accuracy. It’s suitable for functional prototypes, end-use parts, and production runs requiring high-quality surface finishes and mechanical properties.

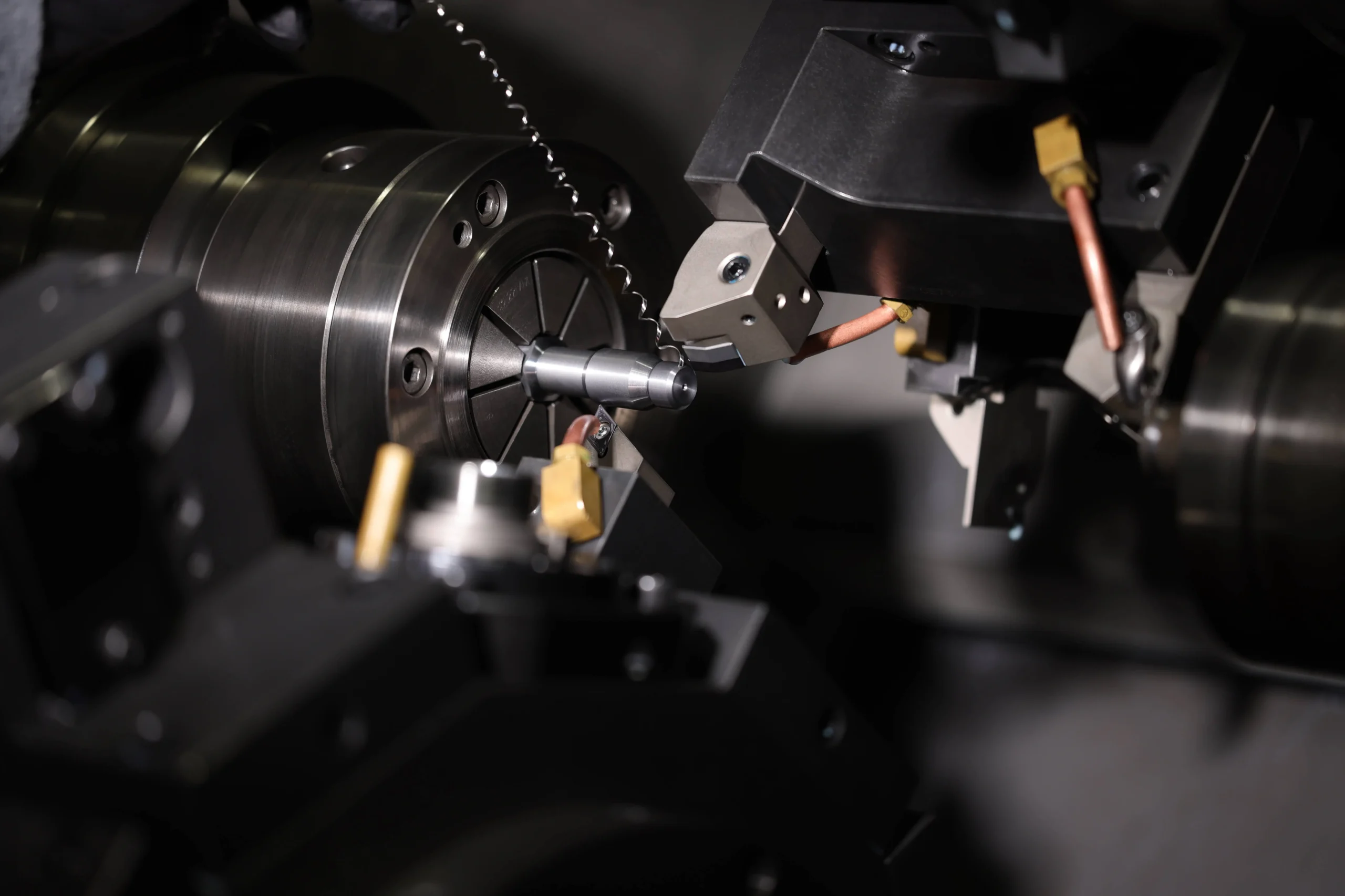

Metal 3D Printing Processes

In addition to polymer-based processes, metal 3D printing offers advanced solutions for creating complex metal parts with exceptional precision and performance. Let’s explore one of the leading metal 3D printing technologies:

Electron Beam Melting (EBM)

EBM uses an electron beam to selectively melt metal powder layer by layer, resulting in fully dense metal parts with superior mechanical properties. It’s widely used in aerospace, automotive, and medical industries for producing complex components with high strength-to-weight ratios and intricate geometries.

When to Use 3D Printing

Knowing when to leverage 3D printing in the manufacturing process is critical for maximising its benefits. 3D printing is best suited for:

Rapid Prototyping

Iterating quickly on design concepts and validating ideas before committing to full-scale production.

Complex Geometries

Creating parts with intricate designs and complex geometries that are difficult or impossible to achieve using traditional manufacturing methods.

Low-Volume Production

Producing small batches of customised or specialised parts with minimal tooling costs and lead times.

Customization and Personalization

Tailoring products to meet specific customer needs and preferences, from medical implants to consumer electronics.

On-Demand Manufacturing

Responding rapidly to changing market demands and producing parts on-demand, reducing inventory costs and waste.

The Benefits of 3D Printing

The advantages of 3D printing extend far beyond rapid prototyping and low-volume production. Here are some key benefits that companies can leverage:

Design Freedom

3D printing enables designers to break free from traditional manufacturing constraints and explore new possibilities in product design and development.

Time and Cost Savings

By streamlining the production process and eliminating the need for tooling, 3D printing reduces lead times, lowers costs, and increases overall efficiency.

Sustainability

Additive manufacturing generates less waste compared to traditional manufacturing methods, contributing to environmental sustainability and resource conservation.

Applications and Uses of 3D Printing

Aerospace and Defence

Manufacturing lightweight, complex components for aircraft, spacecraft, and military equipment.

Automotive

Producing prototypes, tooling, and end-use parts for vehicles, from concept cars to production models.

Healthcare and Medical

Creating custom implants, prosthetics, and medical devices tailored to individual patients’ needs.

Consumer Goods

Designing and manufacturing consumer electronics, wearables, and household products with innovative features and functionalities.

Architecture and Construction

Building scale models, architectural prototypes, and custom components for construction projects.

From aerospace components to medical implants and consumer electronics, 3D printing continues to revolutionise the way products are designed, prototyped, and manufactured. As technology advances and new materials become available, the possibilities for additive manufacturing are limitless.

As we’ve explored the diverse landscape of 3D printing processes and their applications, it’s clear that additive manufacturing holds immense potential for transforming the manufacturing industry. Whether it’s accelerating innovation through rapid prototyping, producing complex geometries with precision, or customising products to meet individual needs, 3D printing offers solutions to challenges that were once thought impossible to overcome.

Ready to unlock the full potential of additive manufacturing? Contact us today to explore our cutting-edge 3D printing solutions and take your manufacturing capabilities to new heights.

Related Posts

June 3, 2024

What is Cold Spray? | Comprehensive Overview

What is cold spray? Cold spray is an advanced coating and additive…

June 2, 2024

17 CNC Machining Materials | Comprehensive Guide

Selecting the right CNC machining materials material is crucial to the success…

June 1, 2024

CNC Machining Tolerances | Comprehensive Guide

CNC machining tolerances are essential for achieving the desired precision and…