In the dynamic world of CNC manufacturing, precision, efficiency, and flexibility are paramount. At Bredo, based in Melbourne, Australia, we pride ourselves on offering state-of-the-art jobbing and production services tailored to meet the diverse needs of businesses across the region. Let’s delve into how our expertise in jobbing and production can revolutionise your CNC manufacturing experience.

Custom Solutions for Every Project Size

Whether you’re embarking on a one-off custom project or need a large run of precision components, Bredo has you covered. Our team of experienced CNC technicians is equipped to handle projects of all sizes, ensuring that each custom item meets the highest standards of quality and precision while keeping costs reasonable.

Efficient Jobbing Techniques

Jobbing, the production of customised items or small batches, is a cornerstone of our manufacturing process. While jobbing may traditionally be less efficient than large-scale production, our skilled technicians ensure that your project is completed with optimal efficiency and precision. From simple prototypes to ambitious undertakings, we strive to deliver exceptional results within a reasonable turnaround time.

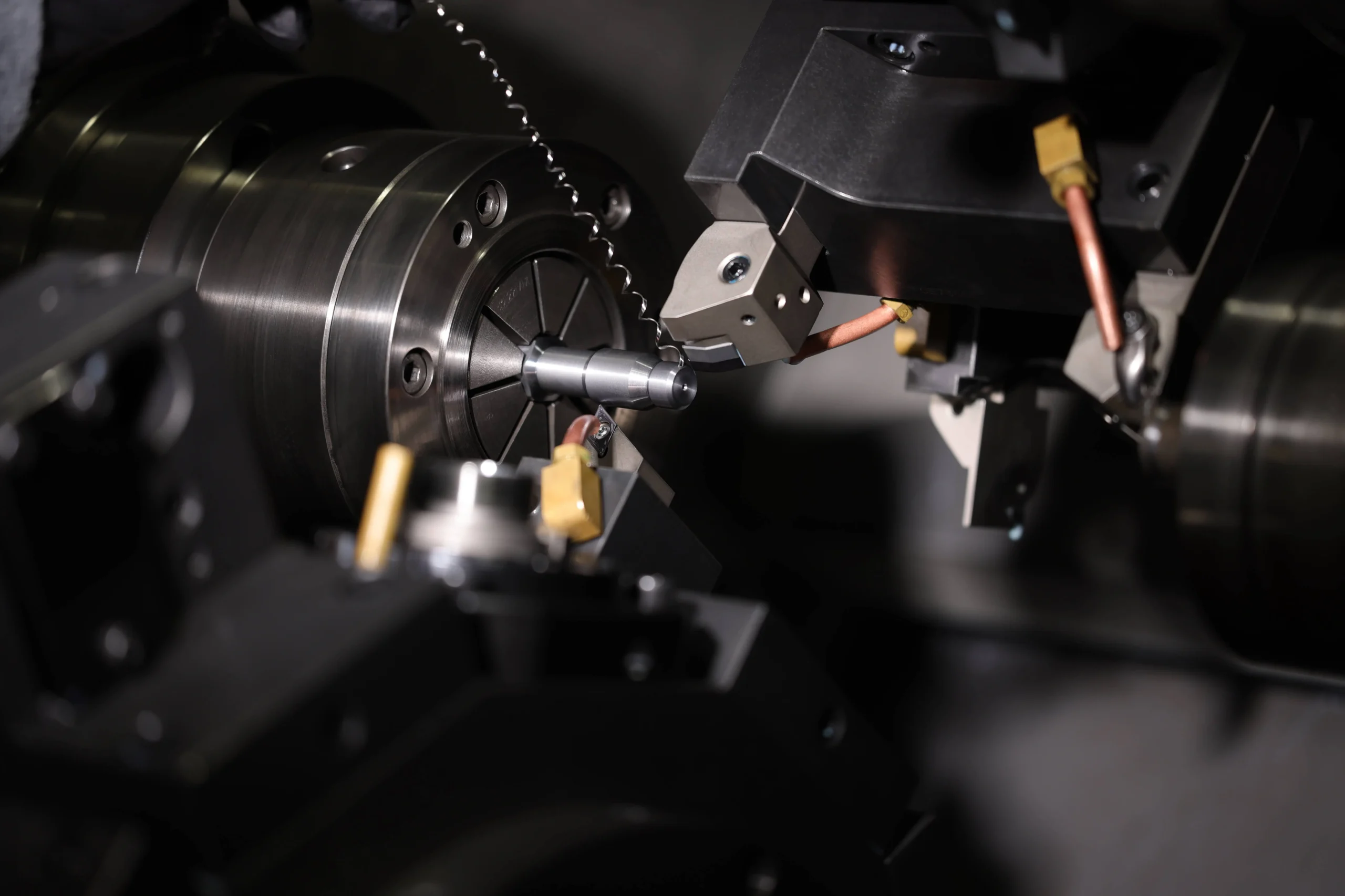

Cutting-Edge Manufacturing Equipment

At the heart of our jobbing and production capabilities lies our cutting-edge manufacturing equipment. With state-of-the-art CNC machines from renowned brands such as Okum, Star, Citizen, and Micro-Vu, we have the tools to bring your custom projects to life with unparalleled precision and quality. Our diverse selection of equipment enables us to handle production runs of any scale, delivering consistent results with every project.

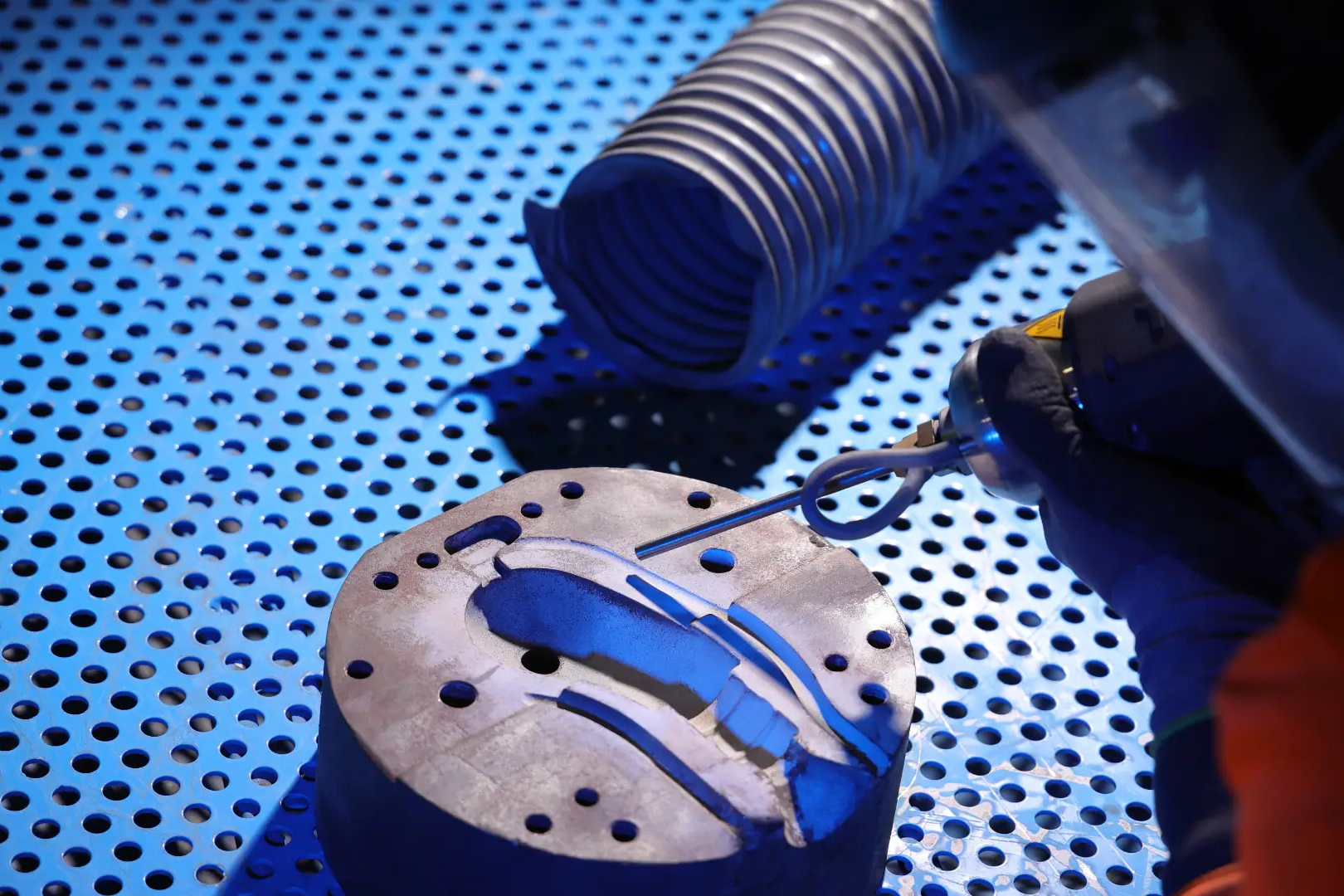

Stringent Quality Control Measures

Quality is non-negotiable at Copamate – Bredo. We employ modern quality control equipment to meticulously monitor every stage of the production process, ensuring consistency and adherence to your specifications. Our American-made Vertex 420CMM coordinate measuring machine, boasting a measuring accuracy of 2 microns, provides precise quality control oversight, giving you peace of mind that your project is in capable hands.

Streamlined Jobbing and Production Process

Our jobbing and production process is designed for maximum efficiency and quality. From initial machining to final quality control checks, our experienced CNC technicians meticulously oversee every step of your project, ensuring seamless execution and timely delivery. We leverage batch production techniques to complete multiple stages of your project simultaneously, reducing lead times and costs without compromising on quality.

At Bredo, we’re committed to delivering superior jobbing and production services that exceed your expectations. With our state-of-the-art equipment, experienced technicians, and unwavering dedication to quality, we empower businesses to achieve their CNC manufacturing goals with confidence. Contact us today to learn more about how our jobbing and production expertise can elevate your next custom project.

Related Posts

June 3, 2024

What is Cold Spray? | Comprehensive Overview

What is cold spray? Cold spray is an advanced coating and additive…

June 2, 2024

17 CNC Machining Materials | Comprehensive Guide

Selecting the right CNC machining materials material is crucial to the success…

June 1, 2024

CNC Machining Tolerances | Comprehensive Guide

CNC machining tolerances are essential for achieving the desired precision and…