CNC machining has become an indispensable technology in modern manufacturing, offering unparalleled precision and efficiency in producing a wide range of parts and components. However, one common question that arises among clients is: How long does CNC machining take? In this blog post, we’ll explore the factors that influence lead times in CNC machining and provide insights into what to expect when utilising this state-of-the-art manufacturing process.

Understanding CNC Machining Lead Times

Lead times in CNC machining refer to the duration it takes from the initial request for a part to its completion and delivery. Understanding these lead times is crucial for planning and managing production schedules effectively. Several factors influence CNC machining lead times, each contributing to the overall timeframe required to produce a part. Here are the key factors that affect CNC machining lead times:

Factors Influencing Lead Times

- Part Complexity: Intricate parts with complex geometries may require more machining time, leading to longer lead times. Conversely, simpler parts can be machined more quickly.

- Material Availability: The availability of the required raw materials can impact lead times. If a specific material is readily available, the machining process can proceed without delays. However, sourcing rare or exotic materials may extend lead times.

- Machine Setup Time: Setting up CNC machines for a new job involves programming, tooling setup, and calibration, which can take time. Complex setups may require additional adjustments, contributing to longer lead times.

- Workload: The workload of the machining facility also plays a significant role in lead times. Busy facilities with high demand may have longer lead times compared to those with lower workloads.

Material Availability

The availability of the required material can significantly impact lead times. Common materials like aluminium, steel, and plastics are usually readily available, while specialized or exotic materials might require longer procurement times. Factors to consider include:

- Stock Levels: In-house availability of materials can shorten lead times, whereas sourcing from external suppliers may cause delays.

- Material Specifications: Custom or specific material grades and sizes may take additional time to source.

Machine Setup Time

Machine setup time refers to the duration required to prepare the CNC machine for a specific job. This includes installing the necessary tooling, programming the machine, and performing initial test runs. Setup times can vary based on:

- Tooling Requirements: The number and type of tools required for the job can affect setup times. Complex setups with multiple tools take longer to arrange.

- Machine Calibration: Precision calibration and alignment of the machine ensure accurate results, adding to the setup time.

- First Article Inspection: Performing an initial inspection of the first produced part to verify it meets specifications can extend setup times.

Workload of the Machining Facility

The current workload and capacity of the machining facility play a crucial role in determining lead times. Factors influencing workload include:

- Production Schedule: Facilities with a high volume of orders may have longer lead times due to queued jobs.

- Machine Availability: Limited availability of specific machines needed for the job can cause scheduling delays.

- Shift Patterns: Facilities operating multiple shifts can process orders faster than those with limited working hours.

Additional Factors Influencing Lead Times

Several other factors can affect CNC machining lead times, including:

- Prototyping vs. Production: Prototyping single parts often takes less time compared to setting up and running a full production batch.

- Post-Processing Requirements: Additional processes like heat treatment, anodizing, or assembly add to the overall lead time.

- Quality Control: Comprehensive quality inspections and testing to ensure parts meet specifications can extend lead times.

- Customisation and Design Changes: Custom parts or last-minute design changes require additional programming and setup, increasing lead times.

How Long Does CNC Machining Take?

Lead times for CNC machining can vary depending on the factors mentioned above. Generally, simpler parts with readily available materials may have shorter lead times, ranging from a few days to a couple of weeks. However, complex parts or those requiring unique materials may have longer lead times, extending to several weeks or even months.

Strategies to Reduce Lead Times

To minimize CNC machining lead times, consider the following strategies:

- Early Planning: Plan and communicate your requirements early with the machining facility to secure production slots and materials.

- Simplify Designs: Simplify part designs where possible to reduce machining complexity and setup times.

- Material Standardisation: Use standard materials that are readily available to avoid procurement delays.

- Efficient Communication: Maintain clear and frequent communication with the machining facility to stay updated on progress and address any issues promptly.

- Batch Processing: Group similar parts or processes together to optimize machine setup and reduce overall lead times.

Utilising State-of-the-Art CNC Technology

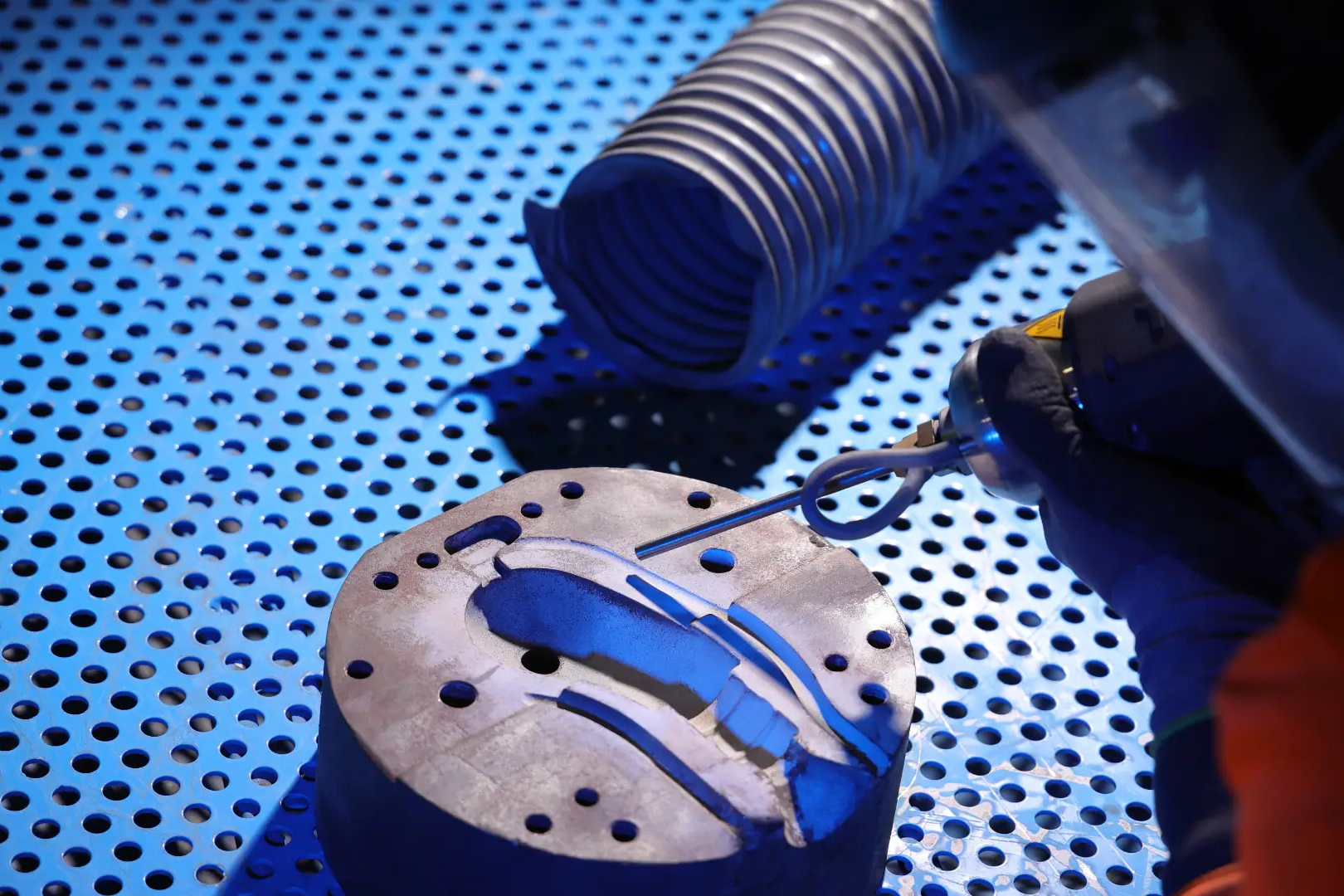

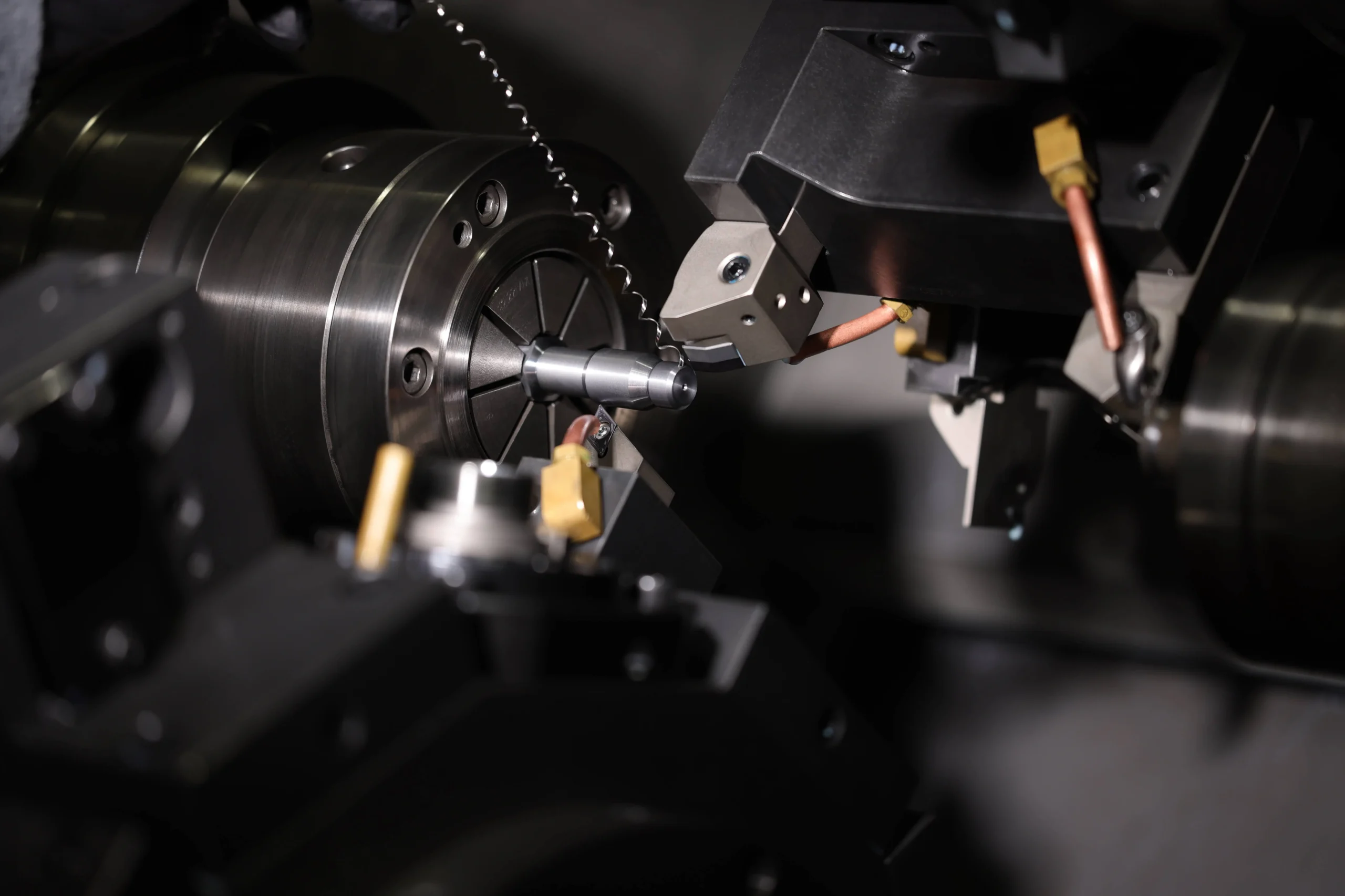

At Bredo in Melbourne, Australia, we leverage state-of-the-art CNC machining technology to optimise lead times and ensure timely delivery of high-quality parts. Our advanced CNC cutting, milling, and turning capabilities enable us to efficiently produce parts with precision and accuracy.

While lead times for CNC engineering can vary based on several factors, understanding the complexities involved in the process can help manage expectations and plan accordingly. By partnering with a reputable CNC machining provider like Bredo, clients can benefit from streamlined processes, reduced lead times, and superior quality parts.

For more information on CNC machining lead times or to discuss your manufacturing needs, contact Bredo today.

Related Posts

June 3, 2024

What is Cold Spray? | Comprehensive Overview

What is cold spray? Cold spray is an advanced coating and additive…

June 2, 2024

17 CNC Machining Materials | Comprehensive Guide

Selecting the right CNC machining materials material is crucial to the success…

June 1, 2024

CNC Machining Tolerances | Comprehensive Guide

CNC machining tolerances are essential for achieving the desired precision and…